Ilya Artemiev: The electric plant is a "Klondike" in transformer engineering

16.08.2023

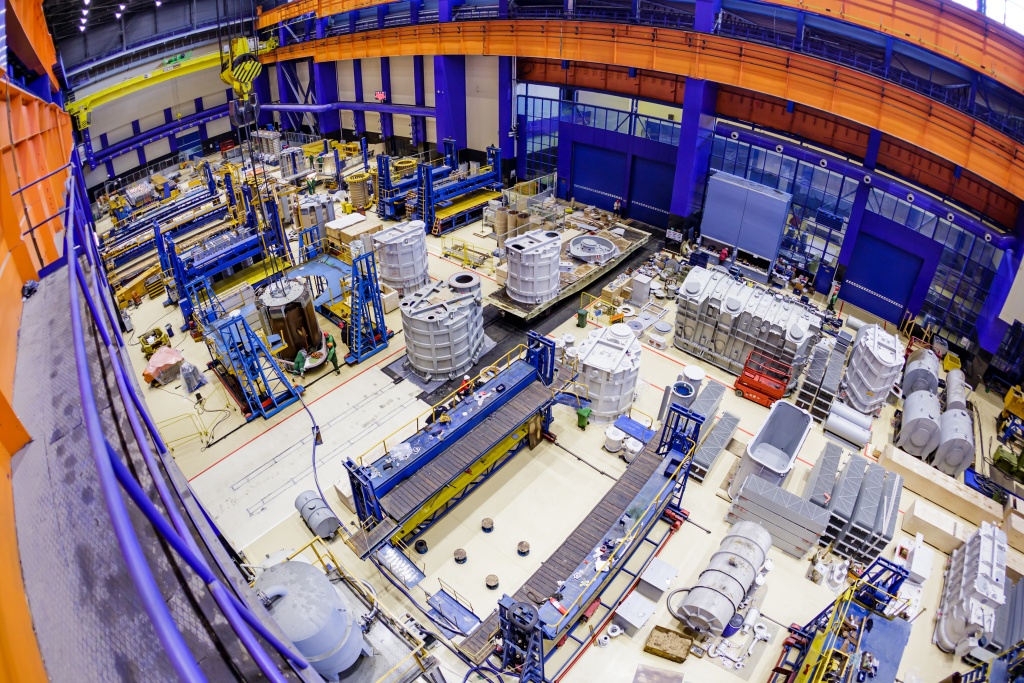

In a few months, the Moscow Electrozavod (part of the ERSO holding) will celebrate its 95th anniversary. Where the flagship of the electrical industry will move, said Ilya Artemyev, general director of the plant.

— Ilya Petrovich, the enterprise that you head today, in fact, has become a driver for the development of the energy sector in our country…

— Of course, the equipment that our factory workers assembled provided all-Union construction sites, enterprises, entire cities and industries. Top quality products have allowed us to seriously and permanently gain a foothold in the industry and become a leader. So, at one of the production facilities, a transformer manufactured in 1941 is still in service. 82 years of uninterrupted service! And that says a lot. The electric plant has become the flagship of heavy engineering for the nuclear industry, the grid and generating sectors, industrial companies and metallurgical industries. We must keep this trend and promote it further.

— What now? What is the future of the Moscow Electrozavod?

— In fact, our plant is a kind of Klondike in the transformer industry. We see in the enterprise large reserves for development in various areas. Today, the energy sector is undergoing major changes, and we are ready to take an active part in them. The plant develops and produces unique designs. Now we are assembling controlled shunt reactors with 330 kV on-load tap-changers for RUE "Brestenergo" and "Vitebskenergo" (Republic of Belarus). There are no analogues of this product on the Russian market yet. And just like that, we immediately swung at international cooperation in new areas and are not going to slow down the pace of development.

Our range is expanding, traction transformers for railway transport appear. We are preparing high-power reactors and transformers for the creation of infrastructure projects related to the Eastern Test Site, BAM. In a short time, we are producing equipment that will expand the transport corridors and capacity of the Baikal-Amur Mainline.

We develop the direction of electric furnace transformers. Recently, one of the unique projects was shipped to the Motovilikha plant. We prepare orders for UC RUSAL, PJSC NLMK, PJSC MMK and other metallurgical enterprises.

Several new directions related to power grid construction are currently being discussed: the production of series compensation devices that can increase the transmission capacity of the line; power take-off transformers that will help reduce the price of technological connection; developments related to mobile and modular substations.

— We have a unique platform, technologies, equipment, and, most importantly, people who are masters of their craft! The contribution of a person to teamwork is highly appreciated. But we are now actively working on putting all our grandiose plans into practice. To do this, the company introduces the system "Lean production". In many ways, it repeats the Japanese system, which is used, for example, in Toyota.

We are also modernizing the production base.

We are still upgrading our staff. Enter experienced employees associated with technology, equipment maintenance, design development and implementation of innovative solutions in the industry. We pay great attention to eliminating downtime. The schedule is very tight, everything is calculated by the minute. Therefore, attention is primarily focused on people, life, well-being, job satisfaction. People are the main and most valuable resource of our company.

— How is the personnel renewal process carried out at the plant?

— A team of great professionals has been assembled at the Electrozavod. Whole families came here, passed on experience, developed skills. Working professions were held in high esteem. The day has come when this tradition needs to be revived. Already, the level of salaries of specialized specialists is quite decent, and we will strengthen this trend. We are actively attracting young people to the plant. We are implementing a mentoring system. Young people should become a driver of growth, and we will motivate our old-timers not only to share experience, but also to be included in the development of the enterprise. These are the most experienced workers of the plant, the experience of these professionals is truly invaluable.

Without those employees who have worked here for a very long time, without the competencies that they have accumulated during their labor activity, growth as a whole is impossible. This is a support and a point of development.

In November this year, the plant will celebrate its 95th anniversary. The contribution made by the electric plant workers to the country's energy system from GOERLO to the present day cannot be overestimated, this is work for centuries, and it will go down in history.

Now we are preparing for our anniversary — we will honor all the employees who worked conscientiously and contributed to the formation and development of the enterprise!

— Ilya Petrovich, the enterprise that you head today, in fact, has become a driver for the development of the energy sector in our country…

— Of course, the equipment that our factory workers assembled provided all-Union construction sites, enterprises, entire cities and industries. Top quality products have allowed us to seriously and permanently gain a foothold in the industry and become a leader. So, at one of the production facilities, a transformer manufactured in 1941 is still in service. 82 years of uninterrupted service! And that says a lot. The electric plant has become the flagship of heavy engineering for the nuclear industry, the grid and generating sectors, industrial companies and metallurgical industries. We must keep this trend and promote it further.

— What now? What is the future of the Moscow Electrozavod?

— In fact, our plant is a kind of Klondike in the transformer industry. We see in the enterprise large reserves for development in various areas. Today, the energy sector is undergoing major changes, and we are ready to take an active part in them. The plant develops and produces unique designs. Now we are assembling controlled shunt reactors with 330 kV on-load tap-changers for RUE "Brestenergo" and "Vitebskenergo" (Republic of Belarus). There are no analogues of this product on the Russian market yet. And just like that, we immediately swung at international cooperation in new areas and are not going to slow down the pace of development.

Our range is expanding, traction transformers for railway transport appear. We are preparing high-power reactors and transformers for the creation of infrastructure projects related to the Eastern Test Site, BAM. In a short time, we are producing equipment that will expand the transport corridors and capacity of the Baikal-Amur Mainline.

We develop the direction of electric furnace transformers. Recently, one of the unique projects was shipped to the Motovilikha plant. We prepare orders for UC RUSAL, PJSC NLMK, PJSC MMK and other metallurgical enterprises.

Several new directions related to power grid construction are currently being discussed: the production of series compensation devices that can increase the transmission capacity of the line; power take-off transformers that will help reduce the price of technological connection; developments related to mobile and modular substations.

— We have a unique platform, technologies, equipment, and, most importantly, people who are masters of their craft! The contribution of a person to teamwork is highly appreciated. But we are now actively working on putting all our grandiose plans into practice. To do this, the company introduces the system "Lean production". In many ways, it repeats the Japanese system, which is used, for example, in Toyota.

We are also modernizing the production base.

We are still upgrading our staff. Enter experienced employees associated with technology, equipment maintenance, design development and implementation of innovative solutions in the industry. We pay great attention to eliminating downtime. The schedule is very tight, everything is calculated by the minute. Therefore, attention is primarily focused on people, life, well-being, job satisfaction. People are the main and most valuable resource of our company.

— How is the personnel renewal process carried out at the plant?

— A team of great professionals has been assembled at the Electrozavod. Whole families came here, passed on experience, developed skills. Working professions were held in high esteem. The day has come when this tradition needs to be revived. Already, the level of salaries of specialized specialists is quite decent, and we will strengthen this trend. We are actively attracting young people to the plant. We are implementing a mentoring system. Young people should become a driver of growth, and we will motivate our old-timers not only to share experience, but also to be included in the development of the enterprise. These are the most experienced workers of the plant, the experience of these professionals is truly invaluable.

Without those employees who have worked here for a very long time, without the competencies that they have accumulated during their labor activity, growth as a whole is impossible. This is a support and a point of development.

In November this year, the plant will celebrate its 95th anniversary. The contribution made by the electric plant workers to the country's energy system from GOERLO to the present day cannot be overestimated, this is work for centuries, and it will go down in history.

Now we are preparing for our anniversary — we will honor all the employees who worked conscientiously and contributed to the formation and development of the enterprise!