Poet Vladimir Mayakovsky wrote eight slogans dedicated to the Electrozavod and its workers, including the slogan:

«Sweep away the slackers and lazybones!

Let's get work of the highest quality!»

In the same year, Vladimir Mayakovsky dedicated his famous "March of shock brigades" to the Electrozavod workers. This march was first published on January 14, 1930 in a factory newspaper, and then included in the poet's collection.

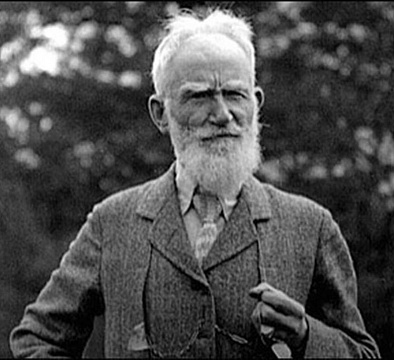

In different years and on different occasions prominent figures of Soviet literature came to the plant: L. Leonov, F. Gladkov, A. Novikov-Priboy, M. Shaginyan, L. Seifullina, K. Paustovsky, V. Lidin, A. Karavaeva, A. Gaidar and others, and Alexey Maksimovich Gorky was enrolled at the plant as an honorary welder.

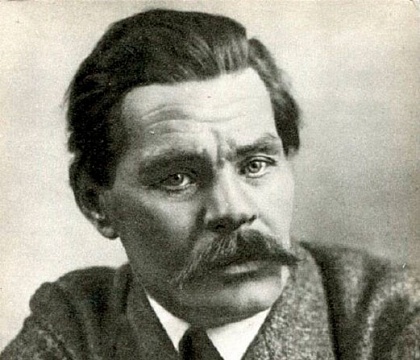

T.S. Lennox, a consulting engineer from "General Electric" company (GE, USA), who had worked at the Plant until 1933 and had contributed much to the training of engineers and establishment of the Plant, came to the Plant. In the photo Lennox surrounded by engineers and future designers of the plant. Standing: K. Brekhov, V. Yastrebov, A. Trostyansky, A. Menis, G. Spuv, E. Balashov, A. Sapozhnikov, sitting: B. Gelperin, S. Rabinovich, T. Lennox, A. Koritsky, L. Schnitzer, J. Kronhaus.

On September 30, 1930 in the Bolshoy Theater a gala evening of shock workers of Electrozavod was held.

On October 3, 1930, the plant was awarded the Order of Lenin for its dedicated patronage work on the line of the State Association of Soviet Grain Farms.